FERMENTER:FUNCTIONS,TYPES,DESIGN& CONSTRUCTION:

Table of Contents

ToggleIntroduction: A fermenter, also known as a fermentation vessel (or closed cylindrical vessel), is a specialized piece of equipment used in various industries, particularly in biotechnology, pharmaceuticals, and food and beverage production. Its primary purpose is to facilitate the controlled growth of microorganisms, such as bacteria, yeast, and fungi, under specific environmental conditions. This controlled environment enables the microorganisms to carry out various biochemical processes, including fermentation, which results in the production of valuable products such as antibiotics, enzymes, biofuels, and alcoholic beverages.

Definition: A fermenter is a cylindrical vessel specifically designed for the cultivation of microorganisms under controlled conditions to facilitate fermentation processes for the production of various products.

Basic Function: The main function of the fermenter-Providing controlled environment for the growth & gene expression of the microorganisms or animal cells, so that desired product can be obtained.

Designing & construction of Fermenter:

Following point must be considered during designing and construction of a fermenter:

- The vessel or fermenter must be capable that aseptically operated for no. of days till operation required. And should be well founded in long-term operation and meet the requirements of containment regulations.

- Sufficient aeration and agitation should be provided to meet all the metabolic requirement of the microorganisms. However, mixing should not cause damage to the microorganism.

- Power consumption should be minimum as much as possible.

- A system for temperature controlled and pH controlled should be provided.

- Vessel should have proper sampling facility.

- Evaporation losses from fermenter should not be more.

- The vessel should be design in such a way that minimal requirement of labours during operation, harvesting, cleaning & maintenance.

- The cheapest and best material should be used which must be comply the whole requirement. And the vessel internal surface constructed to ensure smoothness, using welding’s instead of flange joints whenever possible.

Body construction:

The material for body construction of fermenter should be corrosion proof and material can withstand repeated steam sterilization cycles.

According to American Iron & steel institute (AISI), Steel containing less than 4% chromium are classified as Steel alloys and those containing more than 4% are classified as stainless steels.

The inclusion of nickel in chromium containing steel in high percentage enhances their properties. The corrosion resistance and other properties required for fermenter in steel can be improved by molybdenum, tungsten, silicon and other elements.

Note: – AISI grade 316 steels mainly used for fermenter contains 18% chromium,10% nickel, and 2-2.5 % molybdenum is now commonly used in fermenter construction. AISI grade 304, which contains 18.5% chromium and 10 % nickel which is used for brewing equipments.

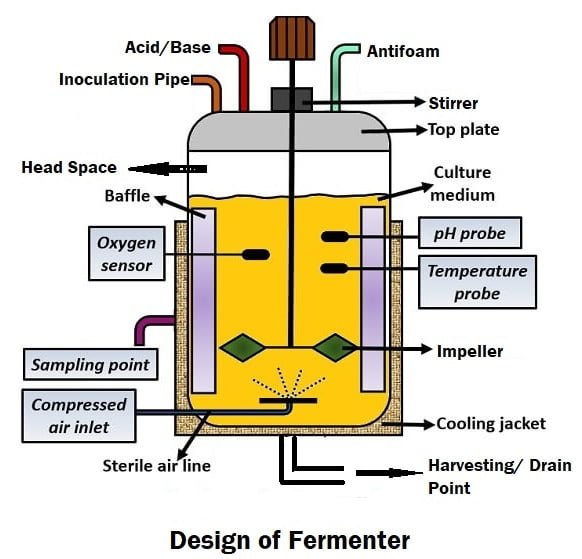

Component/parts of fermenter:

The fermenter includes following components

1) Basic components: – The basic components required for the construction of an ideal fermenter, which involves:

- Top plate:

- Drive motor

- Inoculation pipe

- Impeller shaft

- Stirrer/Agitator/Impeller

- Sparger

- Baffle

- Sample point

- Drain point

- Jacket

- Seal

- Feed Port

- Valves and Steam trap

2) Controlling components: are those components which are required for the monitoring of parameters like temperature, Dissolved oxygen, pH, pressure etc. and it includes:

- Temperature Sensor

- Pressure Sensor

- pO2 oxygen sensor

- Foam sensor

- pH probe

Role of Fermenter components:

- Top plate: It basically covers the top of fermenter made of Stainless steel, which comprises ports, vent lines, View glass, man-holes, etc.

- Drive motor: It drives the impeller shaft.

- Inoculation pipe: Transfer of inoculum through this inoculum port.

- Impeller shaft: It holds the agitator centrally.

- Agitator (Impeller): It is required to achieve no of mixing objectives like-Bulk fluid & gas phase mixing, Oxygen transfer, Heat transfer, It helps to maintain uniform environment throughout the vessel. Types of agitators: a) Disc turbine b) Vaned Disc c) Open turbines of variable pitch d) Propellers e) Other modern Developed agitators: Scaba agitator, Prochem Maxflo-T, Lightining A315, Ekato Intermig

- Sparger: is a device for introducing air into the liquid in a fermenter. There are three basic types of spargers have been used: a) Porous sparger b) Orifice sparger c) Nozzle sparger

- Baffle: Baffles are used to prevent a vortex formation and to improve the aeration efficiency.

- Sample Point: Sampling arrangement are made in fermenter having sample point which allows sample to collect aseptically.

- Drain Point: To withdraw or harvest medium or drain the solution after CIP from fermenter.

- Jacket: In order to balance the heat produced during the process or to maintain the required temperature during process, jacket is installed externally to the fermentation tank and enables the passage of steam or water (chilled water or hot water).

- Seal: Seal is important to maintain the integrity of fermenter. It is used for sealing of the stirrer shaft assembly. Basically, four types of seal assembly have been used. a) Stuffing box (packed gland seal) b) Simple bush seal c) Magnetic seal d) Mechanical seal

- Mechanical Seal: Most commonly used now in both small and large fermenters. This seal is composed of two parts, one part is stationary in the bearing housing and the other part rotates on the shaft. Steam condensate (contains in seal pot during seal sterilization) is used to lubricate and keep cool to the seal during operation.

- Feed Ports: Feed ports and associated piping are usually integrated in a large fermenter for addition of acid/base, nutrients. This is sterilized along with vessel SIP. In small fermenters, addition is made via silicone tubes which are autoclaved separately & pumped by a peristaltic pump after aseptic connection.

- Valves and Steam traps: Valves are attached to the fermenter and ancillary equipments for the controlling the flow of liquid and gases in a different way like: a) Valves which controlling based on flow rates. b) Simple ON/OFF valves, which can be either fully ON or OFF. c) Valves which may be adjusted very precisely on percentage basis Open & Close. Following types of valves used by industries: Gate valve, Globe valve, Piston Valve, Needle Valve, Plug Valve, Ball Valve, Butterfly Valve, Pinch Valve, Diaphragm Valve, Check Valve, Pressure control valve (Pressure control valves & Pressure reduction valves), Safety valves, Steam trap.

- Safety Valve: Safety valves are installed into every air or steam line and vessel. This valve ensure that pressure will never exceed the safe limit recommended by the manufacturer.

- Steam traps: It collects and remove the condensate from steam lines.

Tank Design consideration/ Aspect ratio:

The aspect ratio of a fermenter refers to the ratio of its height to its diameter or width. This ratio plays a significant role in the design and functionality of fermenters, influencing factors such as mixing efficiency, mass transfer, and overall performance. Different aspect ratios are preferred based on the type of fermentation, the characteristics of the microorganisms, and the desired product. Following are the fermenter aspect ratios are balanced to optimize design and function:

- High Aspect Ratio (Tall and Narrow): A fermenter with a high aspect ratio (tall and narrow) typically has a larger height compared to its diameter. This design has several implications:

- Improved Mixing Efficiency: The taller column enhances vertical mixing, which can be advantageous for maintaining uniform distribution of nutrients and oxygen throughout the culture medium. It reduces the formation of concentration gradients.

- Reduced Shear Stress: Taller vessels often have lower shear stress on the microorganisms compared to wider vessels with higher agitation speeds. This is especially important for shear-sensitive microorganisms, like some fungal cultures.

- Limited Oxygen Transfer: The taller vessel might have limitations in oxygen transfer efficiency, especially in the lower regions of the vessel. Additional aeration strategies might be required to ensure optimal oxygen availability for aerobic cultures.

- Reduced Surface Area-to-Volume Ratio: A higher aspect ratio generally results in a smaller surface area relative to the volume. This can impact heat transfer and temperature control, potentially requiring more sophisticated heating and cooling systems.

- Low Aspect Ratio (Short and Wide): A fermenter with a low aspect ratio (short and wide) has a relatively smaller height compared to its diameter. This design brings its own set of advantages and considerations:

- Enhanced Oxygen Transfer: Wider vessels allow for better oxygen transfer rates due to increased surface area at the liquid-air interface. This is particularly beneficial for aerobic cultures that demand high oxygen concentrations.

- Easier Temperature Control: Wider vessels provide more surface area for efficient heat transfer. Temperature control is often easier to achieve, especially with larger-scale fermenters.

- Reduced Vertical Mixing: While horizontal mixing is generally effective, vertical mixing might be compromised due to the shorter column height. This can lead to concentration gradients and uneven nutrient distribution.

- Higher Shear Stress: Wider vessels might require higher agitation speeds for efficient mixing, leading to increased shear stress on the microorganisms. Careful control is needed to prevent damage.

Balancing the Aspect Ratio: The choice of aspect ratio depends on multiple factors, including the nature of the microorganisms, oxygen requirements, heat transfer considerations, and desired product outcomes. Designers aim to strike a balance between mixing efficiency, oxygen transfer, shear stress, and temperature control. For example, if efficient mixing is crucial, a higher aspect ratio might be preferred, whereas oxygen-demanding cultures might necessitate a lower aspect ratio.

In modern fermenter design, computer simulations and advanced engineering techniques are employed to optimize the aspect ratio and other dimensions to achieve the desired performance and product yield. Ultimately, the aspect ratio becomes a critical variable in ensuring the success of fermentation processes and the production of valuable bioproducts.

Note:

1) Impeller Diameter to tank diameter ratio= 0.20 to 0.60

2) Dual impeller should be used when the height of liquid to tank diameter ratio exceeds more than 1.2.

3) Baffles are normally 1/10th of the vessel diameter and attached radially to the vessel wall.

Types of fermenters:

Based on Operation Mode:

- Batch Fermenter: In a batch fermenter, a fixed amount of substrate and microorganisms are introduced at the beginning of the fermentation process. The culture is allowed to grow and metabolize until the desired product is produced or the nutrients are depleted.

- Continuous Fermenter: Continuous fermenters operate in a steady-state manner, with fresh nutrient media continuously supplied, and product is simultaneously harvested. Continuous mode fermentation allows for continuous microbial growth and product production over extended periods.

- Fed-Batch Fermenter: Combining elements of both batch and continuous systems, fed-batch fermenters involve periodic addition of nutrients during the fermentation process. In this ways controlled feeding allows for precise control over growth rates and product accumulation.

Based on Design Principles:

- Stirred Tank Fermenter: Also known as a mechanically agitated fermenter, this type utilizes mechanical stirrers or impellers to maintain uniform mixing of the fermentation broth. It is reasonable for many microbial cultures and applications.

- Airlift Fermenter: Airlift fermenters use air bubbles to create circulation within the vessel, eliminating the need for mechanical agitation. This design is ideal for shear-sensitive microorganisms and minimizes the risk of cell damage.

- Packed Bed Fermenter: Packed bed fermenters involve immobilizing microorganisms on solid support materials within the vessel. Reduced shear stress and improved mass transfer rates is the advantages of this design.

Based on Specific Applications:

- Anaerobic Fermenter: Anaerobic fermenters create an oxygen-free environment, ideal for the growth and metabolism of microorganisms that thrive in the absence of oxygen. These types of fermenters commonly used in the production of biofuels and certain chemicals.

- Aerobic Fermenter: These fermenters provide ample oxygen supply, catering to microorganisms that require oxygen for their metabolic processes. These types of fermenters commonly used for the production of antibiotics, enzymes, and other oxygen-dependent products.

- Solid-State Fermenter: In solid-state fermenters, the microbial culture is grown on a solid substrate rather than in a liquid medium. These types of fermenters commonly used for the production of enzymes, organic acids, and fungal products.

- Submerged Fermenter: In contrast to solid-state fermenters, submerged fermenters culture microorganisms in a liquid medium. This type of fermenters is versatile & generally used for many applications, including the production of pharmaceuticals and bio-based chemicals.

- Animal Cell Culture Bioreactor: These specialized fermenters are designed for the cultivation of animal cells for the production of biopharmaceuticals, monoclonal antibodies, and vaccines.

- Plant Cell Bioreactor: Plant cell fermenters are used to grow plant cells or tissues for the production of secondary metabolites, phytochemicals, and plant-based products.

These diverse types of fermenters cater to the intricate demands of modern biotechnology and industrial processes. By considering the operation mode, design principles, and specific application requirements, scientists and engineers can select the most suitable fermenter to achieve optimal microbial growth and product yield.

For detailed about the types of fermenters feel free to contact us.

Also Read:

Nice article.

Thanks

Nice to read